зғӯй—ЁжҺЁиҚҗ

жЈҖжөӢи®ӨиҜҒдәәи„үдәӨжөҒйҖҡи®ҜеҪ•

жЈҖжөӢи®ӨиҜҒдәәи„үдәӨжөҒйҖҡи®ҜеҪ•

ж·ұеңіnеһӢзўіеҢ–зЎ…иЎ¬еә•_дёҠжө·nеһӢзўіеҢ–зЎ…_дёҠжө·nеһӢзўіеҢ–зЎ…иЎ¬еә•_иұӘйәҰз‘һдҫӣ

- иҝҷзңҹдёҚжҳҜжӮЁйңҖиҰҒзҡ„дә§е“Ғпјҹ

- е“ҒгҖҖгҖҖзүҢпјҡ

- еҗҲж ј

- зӣҙжҺҘжҸҗй—® | еӣһйҰ–йЎөжҗң

- еҮә еҺӮ д»·пјҡ

- 0

- дё»иҰҒи§„ж јпјҡ

- йҪҗе…Ё

- з”ЁгҖҖгҖҖйҖ”пјҡ

ж·ұеңіnеһӢзўіеҢ–зЎ…иЎ¬еә•_дёҠжө·nеһӢзўіеҢ–зЎ…_дёҠжө·nеһӢзўіеҢ–зЎ…иЎ¬еә•_иұӘйәҰз‘һдҫӣ_иӢҸе·һиұӘйәҰз‘һжқҗж–ҷ科жҠҖжңүйҷҗе…¬еҸёдё“дёҡд»ҺдәӢж°§еҢ–й“қзҗғ,ж°§еҢ–й”Ҷзҗғ,йҷ¶з“·зІҫеҠ е·Ҙ,зәәз»Үйҷ¶з“·жҠӣе…үеҠ е·ҘдёҡеҠЎ.иҒ”зі»з”өиҜқпјҡ18962527682 зҪ‘еқҖпјҡwww.homraymaterial.cn

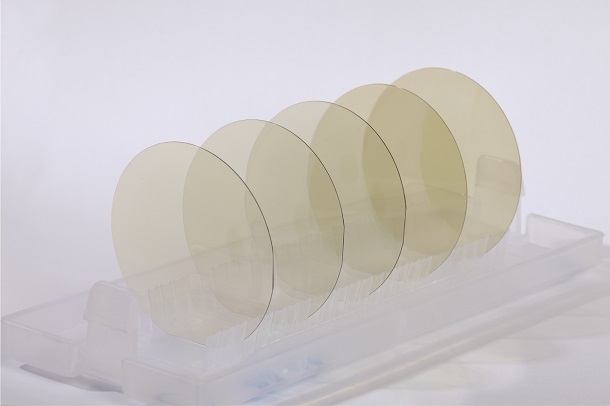

зўіеҢ–зЎ…еҚҠеҜјдҪ“жҳҜж–°дёҖд»Је®ҪзҰҒеёҰеҚҠеҜјдҪ“пјҢе®ғе…·жңүзғӯеҜјзҺҮй«ҳпјҢдёҺGaNжҷ¶ж јеӨұй…Қе°ҸзӯүдјҳеҠҝпјҢйқһеёёйҖӮеҗҲз”ЁдҪңеҸ‘е…үдәҢжһҒз®ЎпјҢеӨ§еҠҹзҺҮз”өеҠӣз”өеӯҗжқҗж–ҷгҖӮ

йҮҮз”ЁзўіеҢ–зЎ…дҪңиЎ¬еә•зҡ„LEDеҷЁд»¶дә®еәҰжӣҙй«ҳгҖҒиғҪиҖ—жӣҙдҪҺгҖҒеҜҝе‘Ҫжӣҙй•ҝгҖҒеҚ•дҪҚиҠҜзүҮйқўз§Ҝжӣҙе°ҸпјҢдё”еңЁеӨ§еҠҹзҺҮLEDж–№йқўе…·жңүйқһеёёеӨ§зҡ„дјҳеҠҝгҖӮжӯӨеӨ–пјҢзўіеҢ–зЎ…йҷӨдәҶз”ЁдҪңLEDиЎ¬еә•пјҢе®ғиҝҳеҸҜд»ҘеҲ¶йҖ й«ҳиҖҗеҺӢгҖҒеӨ§еҠҹзҺҮз”өеҠӣз”өеӯҗеҷЁд»¶еҰӮиӮ–зү№еҹәдәҢжһҒз®ЎпјҲSBD/JBSпјүгҖҒз»қзјҳж …еҸҢжһҒеһӢжҷ¶дҪ“з®ЎпјҲIGBTпјү,жҷ¶й—ёз®ЎпјҲGTOпјүгҖҒйҮ‘еұһж°§еҢ–зү©еҚҠеҜјдҪ“еңәж•Ҳеә”жҷ¶дҪ“з®ЎпјҲMOSFETпјүзӯүпјҢз”ЁдәҺжҷәиғҪз”өзҪ‘гҖҒеӨӘйҳіиғҪ并зҪ‘гҖҒз”өеҠЁжұҪиҪҰзӯүиЎҢдёҡгҖӮ

д»Һж•ҙдҪ“дёҠзңӢпјҢзўіеҢ–зЎ…еҚҠеҜјдҪ“е®Ңж•ҙдә§дёҡй“ҫеҢ…жӢ¬пјҡзўіеҢ–зЎ…еҺҹж–ҷ-жҷ¶й”ӯ-иЎ¬еә•-еӨ–延-иҠҜзүҮ-еҷЁд»¶-жЁЎеқ—гҖӮ

жҲ‘们公еҸёиҝӣеҸЈзўіеҢ–зЎ…жҷ¶еңҶпјҢдёәжҲ‘们зҡ„е®ўжҲ·жҸҗдҫӣжүҖйңҖзҡ„жқҗж–ҷпјҢи®©е®ўжҲ·еңЁиҝҷж ·иЎҢдёҡйҮҢдҝғиҝӣжҠҖжңҜзҡ„еҝ«йҖҹжү©еұ•гҖӮ

дә§е“Ғд»Ӣз»Қпјҡ

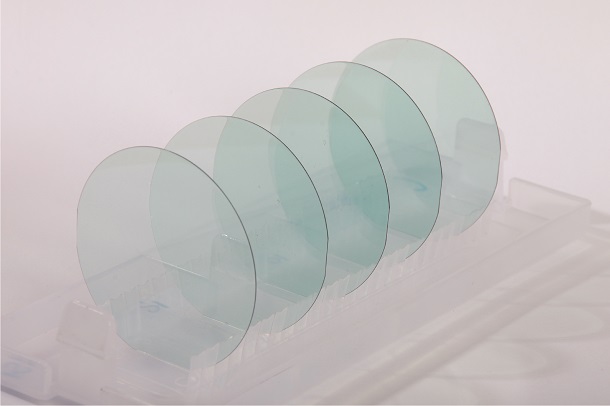

n-type SiC Substrate

PRODUCT DESCRIPTIONS

The Materials Business Unit produces a wide assortment of n-type conductive SiC products ranging in wafer diameters up to 150mm. This material is manufactured upon a high-volume platform process that provides our customers the highest degree of material quality, supply assurance and economies of scale.

Part Number

Description

W4NRF0X-0200

4H-SiC, n-type, Research Grade, 100mm, On-Axis, 0.013-2.0 ohm-cm, Standard MPD, 500um Thick, DoubleSided Polish Si Face CMP Epi Ready, Bare Substrate

W4NRF4C-U200

4H-SiC, n-type, Research Grade, 100mm, 4В° Off-Axis, 0.015-0.028 ohm-cm, Ultra Low MPD вүӨ1/cm2, 350um Thick, Double-Sided Polish Si Face CMP Epi Ready, Bare Substrate

W4NPF4C-U200

4H-SiC, n-type, Production Grade, 100mm, 4В° Off-Axis, 0.015-0.028 ohm-cm, Ultra Low MPD вүӨ1/cm2, 350um Thick, Double-Sided Polish Si Face CMP Epi Ready, Bare Substrate

W4NRF4C-B200

4H-SiC, n-type, Research Grade, 100mm, 4В° Off-Axis, 0.015-0.028 ohm-cm, Ultra Low MPD вүӨ1/cm2, Low BPD вүӨ1500/cm2, 350um Thick, Double Sided Polish Si Face CMP Epi Ready, Bare Substrate

W4NPF4C-B200

4H-SiC, n-type, Production Grade, 100mm, 4В° Off-Axis, 0.015-0.028 ohm-cm, Ultra Low MPD вүӨ1/cm2, Low BPD вүӨ1500/cm2, 350um Thick, Double-Sided Polish Si Face CMP Epi Ready, Bare Substrate

W4NRG4C-C1-V200

4H-SiC, n-type, Research Grade, 150mm, 4В° Off-Axis, 0.015-0.028 ohm-cm, Very Low MPD вүӨ5/cm2, 350um Thick w/ 47.5mm Flat, Double-Sided Polish Si Face CMP Epi Ready, Bare Substrate

W4NPG4C-C1-V200

4H-SiC, n-type, Production Grade, 150mm, 4В° Off-Axis, 0.015-0.028 ohm-cm, Very Low MPD вүӨ5/cm2, 350um Thick w/ 47.5mm Flat, Double-Sided Polish Si Face CMP Epi Ready, Bare Substrate

W4NRG4C-C1-U200

4H-SiC, n-type, Research Grade, 150mm, 4В° Off-Axis, 0.015-0.028 ohm-cm, Ultra Low MPD вүӨ1/cm2, 350um Thick w/ 47.5mm Flat, Double-Sided Polish Si Face CMP Epi Ready, Bare Substrate

W4NPG4C-C1-U200

4H-SiC, n-type, Production Grade, 150mm, 4В° Off-Axis, 0.015-0.028 ohm-cm, Ultra Low MPD вүӨ1/cm2, 350um Thick w/ 47.5mm Flat, Double-Sided Polish Si Face CMP Epi Ready, Bare Substrate

*C-faced polished wafers and 150mm LBPD substrates available upon request, lead times dependent on volume and requirements

FLAT LENGTH

Linear dimension of the flat measured with ANSI-certified digital calipers on a sample of one wafer per ingot

PRIMARY FLAT

The flat of the longest length on the wafer, oriented such that the chord is parallel with a specified low-index crystal plane.

PRIMARY FLAT ORIENTATION

The primary flat is the {1010} plane with the flat face parallel to the <1120> direction. Measured with Laue back reflection technique.

SECONDARY FLAT

A flat of shorter length than the primary flat, whose position with respect to the primary flat identifies the face of the wafer. Not applicable to 150mm wafers.

SECONDARY FLAT ORIENTATION

The secondary flat is the {11-20} plane with the flat face parallel to the <1010> direction. Measured with Laue back reflection technique.

MARKING

For silicon-face polished material, the carbon face of each individual wafer is laser-marked with OCR-compatible font, similar to definitions and characteristics in SEMI M12. For carbonface-polished material, the silicon face of each individual wafer is laser-marked.

PRODUCT SPECIFICATIONS

100mm Diameter n-type Substrates

Diameter

100.0 mm +0.0/-0.5 mm

Thickness

On-axis

500 Ојm Вұ 25 Ојm

Off-axis

350.0 Ојm Вұ 25.0 Ојm

Dopant

Nitrogen

Primary flat length

32.5 mm Вұ 2.0 mm

Secondary flat length

18.0 mm Вұ 2.0 mm

Surface orientation

On-axis

{0001} Вұ 0.25Лҡ

Off-axis

4.0Лҡ toward <1120> Вұ 0.5Лҡ

Surface finish

Back face optical polish, epi-face CMP

Orthogonal misorientation

Вұ 5.0Лҡ

Primary flat orientation

<1120> Вұ 5.0Лҡ

Secondary flat orientation

90.0Лҡ CW from primary Вұ 5.0Лҡ, silicon face up

TTV

вүӨ15 microns, full substrate

Warp

вүӨ45 microns, full substrate

LTV (average, 1 cm2 site)

вүӨ4 microns, full substrate

Edge chips by diffuse lighting

Production-grade

none permitted вүҘ0.5mm width and depth

Research-grade

qty. 2 вүҘ1.0 mm width and depth

150mm Diameter n-type Substrates

Diameter

150.0 mm Вұ 0.25 mm

Thickness

C1 specification

350 Ојm Вұ 25 Ојm

Dopant

Nitrogen

Primary flat length

47.5 mm Вұ 1.5 mm

Secondary flat length

None

Surface orientation

4.0Лҡ toward <11-20> Вұ 0.5Лҡ

Surface finish

Back face optical polish, epi-face CMP

Orthogonal misorientation

Вұ 5.0Лҡ

Primary flat orientation

<11-20> Вұ 5Лҡ

Secondary flat orientation

N/A

TTV

вүӨ10 Ојm

Warp

Production-grade

вүӨ40 Ојm

Research-grade

вүӨ60 Ојm

LTV (average, 1 cm2 site)

Production-grade

вүӨ2 Ојm

Research-grade

вүӨ4 Ојm

Edge chips by diffuse lighting

Production-grade

none permitted вүҘ0.5mm width and depth

Research-grade

qty. 2 вүҘ1.0 mm width and depth

иӢҸе·һиұӘйәҰз‘һжқҗж–ҷ科жҠҖжңүйҷҗе…¬еҸёз®Җд»ӢпјҡиӢҸе·һиұӘйәҰз‘һжқҗж–ҷ科жҠҖжңүйҷҗе…¬еҸёжҳҜдёҖ家专дёҡд»ҺдәӢж°§еҢ–й“қгҖҒж°§еҢ–й”Ҷдә§е“ҒгҖҒејҖеҸ‘ еҲ¶йҖ гҖҒй”Җе”®дәҺдёҖдҪ“зҡ„дјҒдёҡпјҢдјҒдёҡжңүеӣҪеҶ…еүҚеҲ—зҡ„е·ҘиүәпјҢдё“дёҡзҡ„жҠҖжңҜдәәе‘ҳпјҢе…Ҳиҝӣзҡ„з”ҹдә§и®ҫеӨҮе’ҢжЈҖжөӢжүӢж®өгҖӮжҲ‘е…¬еҸёз”ҹдә§зҡ„дә§е“Ғдё»иҰҒжңүпјҡе·Ҙдёҡз”Ёеҗ„зұ»ж°§еҢ–й“қзІүеҢ…жӢ¬пјҲи“қе®қзҹій•ҝжҷ¶з”ЁзІүпјҢжҠӣе…үз”ЁзІүпјҢжҠӣе…үж¶Із”Ёж°§еҢ–й“қзІүпјҢзүҮзҠ¶ж°§еҢ–й“қзІүвҖҰвҖҰпјү,з ”зЈЁз”Ёж°§еҢ–й“қзҗғпјҢз ”зЈЁз”Ёж°§еҢ–й”ҶзҗғпјҢж°§еҢ–й“қйҷ¶з“·д»¶пјҢзІҫеҜҶж°§еҢ–й“қйҷ¶з“·пјҢдё“дёҡйҷ¶з“·зІҫеҠ е·ҘжңҚеҠЎпјҢзәәз»Үйҷ¶з“·жҠӣе…үзІҫеҠ е·ҘжңҚеҠЎгҖӮ

жҲ‘е…¬еҸёдә§е“ҒйҪҗе…ЁпјҢиў«еӨ§иҢғеӣҙз”ЁдәҺз ”зЈЁгҖҒеҚҠеҜјдҪ“гҖҒеҢ–е·ҘгҖҒжҠӣе…үгҖҒеҲ¶йҖ гҖҒзәәз»ҮзӯүиЎҢдёҡгҖӮз”ұдәҺжҲ‘们зҡ„дә§е“ҒжҖ§иғҪдјҳиүҜпјҢд№…з»ҸиҖҗз”ЁпјҢж·ұеҸ—е№ҝеӨ§з”ЁжҲ·еҘҪиҜ„гҖӮжҲ‘们е°ҶдјҳиҙЁзҡ„дә§е“ҒдёҺжңҚеҠЎеҘүзҢ®е®ўжҲ·пјҢ е°ҪжҲ‘们жҜ”иҫғеӨ§зҡ„еҠӘеҠӣиҫҫеҲ°е®ўжҲ·зҡ„ж»Ўж„ҸгҖӮжҲ‘们еёҢжңӣе»әз«Ӣй•ҝжңҹзҡ„еҸӢеҘҪеҗҲдҪңе…ізі»пјҢж¬ўиҝҺе№ҝеӨ§еӣҪеҶ…еӨ–ж–°иҖҒе®ўжҲ·жқҘз”өе’ЁиҜўеҸҠжқҘеҺӮиҖғеҜҹжҙҪи°Ҳ!иӢҸе·һиұӘйәҰз‘һжқҗж–ҷ科жҠҖжңүйҷҗе…¬еҸёиҒ”зі»ж–№ејҸпјҡ

зҺӢз»ҸзҗҶпјҡ18962527682

еӯҷз»ҸзҗҶпјҡ18626214311

иҒ”зі»з”өиҜқпјҡ0512-65030678

зҪ‘еқҖпјҡwww.homraymaterial.cn

ең°еқҖпјҡиӢҸе·һеёӮе·ҘдёҡеӣӯеҢәе”ҜеҚҺи·Ҝ3еҸ·еҗӣең°е•ҶеҠЎе№ҝеңә5ж Ӣ602е®Ө

зҺӢдёҖйҹ¬

- [иҒ”зі»ж—¶иҜ·иҜҙжҳҺжқҘиҮӘжЈҖжөӢйҖҡ]

- еңЁзәҝе®ўжңҚпјҡ

-

- з•ҷиЁҖе’ЁиҜў

- иҒ”зі»ж–№ејҸпјҡ

-

иҜ·зӮ№еҮ»жҹҘзңӢз”өиҜқ

- йӮ®д»¶пјҡ

- еҸ‘йҖҒйӮ®д»¶

- ең°еқҖпјҡ

- иӢҸе·һеёӮе·ҘдёҡеӣӯеҢәе”ҜеҚҺи·Ҝ3еҸ·еҗӣең°е•ҶеҠЎе№ҝеңә5ж Ӣ602е®Ө

жҺЁиҚҗдә§е“Ғ

- ж·ұеңіж°§еҢ–й”Ҷйҷ¶з“·зҗғз”ҹдә§е•Ҷ_ж·ұеңі

- е№ҝе·һз ”зЈЁж°§еҢ–й”Ҷзҗғ_е№ҝе·һж°§еҢ–й”Ҷ

- еҢ—дә¬й«ҳзІҫеәҰж°§еҢ–й”Ҷзҗғ_иӢҸе·һз ”зЈЁ

- еҢ—дә¬зІҫеҜҶж°§еҢ–й“қзҗғ_еҢ—дә¬95ж°§еҢ–

- иӢҸе·һж°§еҢ–й“қжҠӣе…үж¶І_иӢҸе·һи“қе®қзҹі

- иӢҸе·һи“қе®қзҹіж°§еҢ–й“қжҠӣе…үж¶І_иӢҸе·һ

- ж·ұеңіз ”зЈЁз”Ёж°§еҢ–й”Ҷзҗғ_дёҠжө·ж°§еҢ–

- дёҠжө·й«ҳзәҜж°§еҢ–й”Ҷзҗғ_дёҠжө·ж°§еҢ–й”Ҷ

- дёҠжө·ж°§еҢ–й”Ҷе’Ңж°§еҢ–й“қйҷ¶з“·зҗғ_дёҠ

- е‘је’Ңжө©зү№sicзўіеҢ–зЎ…_е‘је’Ңжө©зү№йңҖ

- д№Ңе…°еҜҹеёғзўіеҢ–зЎ…_д№Ңе…°еҜҹеёғзўіеҢ–

- д№Ңе…°еҜҹеёғзўіеҢ–зЎ…еёӮеңә_д№Ңе…°еҜҹеёғs

- ж— й”ЎзўіеҢ–зЎ…жҷ¶зүҮ_ж— й”ЎзўіеҢ–зЎ…еёӮ

- ж·ұеңіиҖҗзЈЁйҷ¶з“·ж°§еҢ–й“қзҗғ_ж·ұеңіжҠӣ

- ж·ұеңіж°§еҢ–й“қзҗғ з ”зЈЁзҹҝзҹі_ж·ұеңіж°§

-

жЈҖжөӢйҖҡжүӢжңәзүҲ

жЈҖжөӢйҖҡе®ҳж–№еҫ®дҝЎ

жЈҖжөӢйҖҡQQзҫӨ