зғӯй—ЁжҺЁиҚҗ

жЈҖжөӢи®ӨиҜҒдәәи„үдәӨжөҒйҖҡи®ҜеҪ•

жЈҖжөӢи®ӨиҜҒдәәи„үдәӨжөҒйҖҡи®ҜеҪ•

еҚ—жҫіз”өж°”NALCж°”дҪ“пјҲз“Ұдёқпјү继з”өеҷЁеҺӢеҠӣйҮҠж”ҫйҳҖе…ЁиҮӘеҠЁжөӢиҜ•иЈ…зҪ®

- иҝҷзңҹдёҚжҳҜжӮЁйңҖиҰҒзҡ„дә§е“Ғпјҹ

- е“ҒгҖҖгҖҖзүҢпјҡ

- зӣҙжҺҘжҸҗй—® | еӣһйҰ–йЎөжҗң

- еҮә еҺӮ д»·пјҡ

- 0

- дё»иҰҒи§„ж јпјҡ

- з”ЁгҖҖгҖҖйҖ”пјҡ

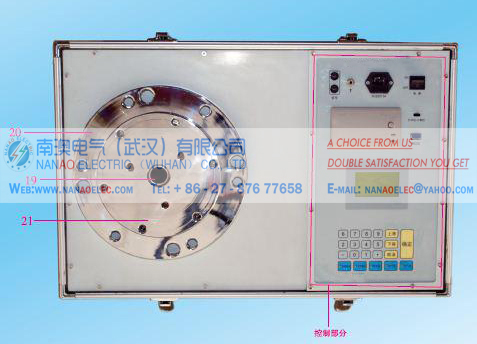

- NALC automatic gas relay pressure relief valve test device еҚ—жҫіз”өж°”NALCж°”дҪ“пјҲз“Ұдёқпјү继з”өеҷЁеҺӢеҠӣйҮҠж”ҫйҳҖе…ЁиҮӘеҠЁжөӢиҜ•иЈ…зҪ®дә§е“Ғзү№зӮ№ Tester Features 1гҖҒNALCеһӢж°”дҪ“继з”өеҷЁжЈҖжөӢеҸ°пјҢйҮҮз”ЁжңҖж–°зҡ„еөҢе…ҘејҸзі»з»ҹжҺ§еҲ¶жҠҖжңҜпјҢз»јеҗҲз”ЁжҲ·зҡ„е®һйҷ…йңҖжұӮиҖҢжҺЁеҮәзҡ„ж–°дёҖд»Јж°”дҪ“继з”өеҷЁиҜ•йӘҢжЈҖжөӢзі»з»ҹгҖӮжң¬зі»з»ҹйҮҮз”ЁдәҶжІ№жіөвҖ”жөҒйҮҸи®Ўиҝһз»ӯжөӢйҮҸж–№жі•пјҢеҸҜеҲҶеҲ«еҜ№ПҶ25гҖҒПҶ50гҖҒПҶ80жҜ«зұіз®Ўеҫ„зҡ„еӣҪеҶ…еӨ–ж°”дҪ“继з”өеҷЁзҡ„жөҒйҖҹгҖҒе®№з§Ҝе’ҢеҜҶе°ҒиҝӣиЎҢжЈҖжөӢпјҢдё”е®һйӘҢиҝҮзЁӢж— йЎ»дәәе·ҘеҸӮдёҺгҖӮ 2гҖҒеөҢе…Ҙзҡ„PCзі»з»ҹпјҢйҮҮз”Ёе…ЁеҪ©и§Ұж‘ёжҳҫзӨәеҷЁпјҢеҸҜз®ҖеҚ•зӣҙи§Ӯзҡ„еҜ№зі»з»ҹиҝӣиЎҢжөҒйҖҹгҖҒе®№з§ҜгҖҒеҜҶе°ҒиҜ•йӘҢзҡ„зӣёе…іж“ҚдҪңпјҢ并еҗҢж—¶зј–иҫ‘жү“еҚ°зӣёе…іжЈҖжөӢжҠҘе‘ҠпјҢдё”еҸҜд»Ҙдҝқеӯҳж•°жҚ®д»ҘдҫҝйҡҸж—¶и°ғйҳ…е’Ңжү“еҚ°гҖӮз”ұдәҺйҮҮз”ЁеөҢе…ҘејҸи®ҫи®ЎпјҢз”ұPCжҺ§еҲ¶пјҢж“ҚдҪңз•ҢйқўеҸӢеҘҪпјҢж•ҙжңәиҮӘеҠЁеҢ–зЁӢеәҰй«ҳзӯүзү№зӮ№гҖӮ еҚ—жҫіз”өж°”NALCж°”дҪ“пјҲз“Ұдёқпјү继з”өеҷЁеҺӢеҠӣйҮҠж”ҫйҳҖе…ЁиҮӘеҠЁжөӢиҜ•иЈ…зҪ®дә§е“Ғз»“жһ„ 1гҖҒз»“жһ„зү№зӮ№ пјҲ1пјүеӨ–йғЁжңәжҹңйҮҮз”ЁеҶ·жүҺжқҝжҠҳиҫ№жҲҗеһӢе·ҘиүәеҲ¶йҖ пјҢеӨ–еҪўе°әеҜё2400Г—650Г—1570mm(й•ҝГ—е®ҪГ—й«ҳ)пјҢж•ҙжңәжҖ»йҮҚ170kgпјӣ пјҲ2пјүеӨ№зҙ§еҷЁйҮҮз”ЁиһәжқҶжЈҳиҪ®ж–№ејҸеӨ№зҙ§иў«иҜ•д»¶пјӣ пјҲ3пјүжІ№з®ұйҮҮз”ЁйқһжүҝеҺӢејҸз»“жһ„пјҢдҫ§йқўи®ҫжңүжІ№дҪҚи®Ўпјӣ пјҲ4пјүеңЁиў«иҜ•д»¶зҡ„е®үиЈ…дҪҚзҪ®еӨ„и®ҫжңүйҳІжҠӨзҪ©пјӣ 2гҖҒз”өж°”еҸҠжҺ§еҲ¶зі»з»ҹ пјҲ1пјүе·ҘдҪңзҺҜеўғпјҡпјҚ10~пјӢ50в„ғпјҢзӣёеҜ№ж№ҝеәҰ<85%пјӣ пјҲ2пјүз”өж°”дё»зәҝи·ҜйҮҮз”ЁAC380VпјҢжҖ»еҠҹзҺҮ11KWпјӣ пјҲ3пјүжІ№жіөз”өжңәйҮҮз”ЁAC380VпјҢеҠҹзҺҮ5.5KWпјӣ пјҲ4пјүз”өеҠЁжү§иЎҢе…ғ件йҮҮз”ЁAC220V/DC24Vз”өжәҗжҺ§еҲ¶пјҢеҠҹзҺҮ0.25KWпјӣ пјҲ5пјүжҺ§еҲ¶зі»з»ҹйҮҮз”ЁAC220V/DC24Vз”өжәҗжҺ§еҲ¶пјҢеҠҹзҺҮ0.25KWпјӣ пјҲ6пјүжІ№еҠ зғӯеҷЁпјҡAC220V,еҠҹзҺҮ5KWпјӣ пјҲ7пјүйҮҮз”Ё19еҜёе…ЁеҪ©и§Ұж‘ёжҳҫзӨәеҷЁпјҢдёӯиӢұж–ҮеӣҫеҪўжҳҫзӨәпјҢж“ҚдҪңиҝҮзЁӢз”ұзі»з»ҹиҮӘеҠЁе®ҢжҲҗпјҢж— йңҖдәәе·Ҙе№Ійў„пјӣ пјҲ8пјүйҮҮз”ЁиҷҡжӢҹжҠ•еҪұй”®йј гҖӮжӯӨжҠҖжңҜдёәдәҢз»ҙжҠ•еҪұжҲҗеғҸпјҢеңЁи§ҰеұҸеүҚж–№зҡ„е·ҘдҪңеҸ°йқўдёҠпјҢжҠ•еҪұеҮәдёҖдёӘзәўиүІдёҺж Үй”®зӣҳеӨ§е°ҸдёҖиҮҙзҡ„иҷҡжӢҹжҠ•еҪұй”®зӣҳпјҢж“ҚдҪңдәәе‘ҳеҸҜз”ЁжӯӨй”®зӣҳеҜ№иҜ•йӘҢжҠҘе‘ҠеҶ…е®№иҝӣиЎҢзј–иҫ‘гҖӮж“ҚдҪңдәәе‘ҳиҝҳеҸҜйҖҡиҝҮжӯӨй”®зӣҳеҝ«жҚ·й”®пјҢе®ҢжҲҗй”®зӣҳе’Ңйј ж Үзҡ„еҲҮжҚўпјҢ并йҖҡиҝҮиҷҡжӢҹй”®зӣҳдёҠзҡ„еҝ«жҚ·й”®е…ій—ӯжҠ•еҪұй”®йј пјҢеҶҚйҖҡиҝҮеӣәе®ҡжүӢеҠҝжү“ејҖгҖӮ пјҲ9пјүеөҢе…ҘPCзі»з»ҹеҸҜзӣҙи§Ӯзҡ„еҜ№йҮҚз“Ұж–ҜжөҒйҖҹгҖҒиҪ»з“Ұж–Ҝе®№з§ҜгҖҒеҜҶе°ҒжЈҖжөӢзҡ„еҚ•йЎ№е’Ңз»јеҗҲйЎ№зӣ®иҝӣиЎҢж“ҚдҪңпјҢ并еҗҢж—¶зј–иҫ‘жү“еҚ°иҜ•йӘҢжҠҘе‘Ҡпјӣ пјҲ10пјүPCзі»з»ҹеҶ…е®үиЈ…з”ұеҚ—жҫіз”өж°”иҮӘдё»ејҖеҸ‘пјҢе…·жңүе®Ңе…ЁзҹҘиҜҶдә§жқғзҡ„дё“дёҡжөӢйҮҸжҺ§еҲ¶иҪҜ件пјҢ并且еҸҜе®һж–ҪзҪ‘з»ңиҝңзЁӢзі»з»ҹеҚҮзә§е’Ңз»ҙжҠӨгҖӮ пјҲ11пјүиҝңзЁӢжҠҖжңҜж”ҜжҢҒпјҡеҰӮзҺ°еңәж“ҚдҪңдәәе‘ҳйңҖиҰҒжҠҖжңҜж”ҜжҢҒпјҢи®ҫеӨҮеҸӘйңҖжҺҘе…ҘеӨ–еӣҙзҪ‘з»ңпјҢиҝңзЁӢз«ҜжҠҖжңҜдәәе‘ҳеҚіеҸҜеҜ№и®ҫеӨҮиҝӣиЎҢиҝңзЁӢж“ҚжҺ§еҸҠи®ҫеӨҮиҪҜ件еҚҮзә§гҖӮ еҚ—жҫіз”өж°”NALCж°”дҪ“пјҲз“Ұдёқпјү继з”өеҷЁеҺӢеҠӣйҮҠж”ҫйҳҖе…ЁиҮӘеҠЁжөӢиҜ•иЈ…зҪ®дё»иҰҒжҠҖжңҜжҖ§иғҪ 1гҖҒжөӢйҮҸиҢғеӣҙ пјҲ1пјүйҮҚз“Ұж–ҜжөҒйҖҹжЈҖжөӢ ПҶ25жҜ«зұіз®Ўеҫ„зҡ„жөҒйҖҹиҢғеӣҙпјҡ0.6~3.9m/sпјӣ ПҶ50жҜ«зұіз®Ўеҫ„зҡ„жөҒйҖҹиҢғеӣҙпјҡ0.6~3.0m/sпјӣ ПҶ80жҜ«зұіз®Ўеҫ„зҡ„жөҒйҖҹиҢғеӣҙпјҡ0.6~2.0m/sгҖӮ пјҲ2пјүиҪ»з“Ұж–Ҝе®№з§ҜжЈҖжөӢ жЈҖжөӢиҢғеӣҙпјҡ0~950mlгҖӮ пјҲ3пјүеҜҶе°ҒжЈҖжөӢеҺӢеҠӣеҸҠж—¶й—ҙиҢғеӣҙ еҜҶе°ҒжЈҖжөӢеҺӢеҠӣиҢғеӣҙпјҡ0~250KPaпјӣ еҜҶе°ҒжЈҖжөӢж—¶й—ҙиҢғеӣҙпјҡ0~60minгҖӮ 2гҖҒзІҫеәҰ пјҲ1пјүжөҒйҖҹжЈҖжөӢзІҫеәҰпјҡ1.5зә§гҖҗеҺӮж Ү1.0зә§гҖ‘пјӣ пјҲ2пјүжөҒйҮҸи®ЎзІҫеәҰпјҡ0.5зә§гҖҗеҺӮж Ү0.2зә§гҖ‘пјӣ пјҲ3пјүйҮҚз“Ұж–ҜжөҒйҖҹйҮҚеӨҚжЈҖжөӢиҜҜе·®пјҡ ПҶ25жҜ«зұіз®Ўеҫ„зҡ„жөҒйҖҹВұ0.05m/sгҖҗеҺӮж ҮВұ0.04m/sгҖ‘пјӣ ПҶ50жҜ«зұіз®Ўеҫ„зҡ„жөҒйҖҹВұ0.04m/sгҖҗеҺӮж ҮВұ0.03m/sгҖ‘пјӣ ПҶ80жҜ«зұіз®Ўеҫ„зҡ„жөҒйҖҹВұ0.02m/sгҖҗеҺӮж ҮВұ0.02m/sгҖ‘гҖӮ пјҲ4пјүйҮҚз“Ұж–ҜжөҒйҖҹжҳҫзӨәдҪҚж•°пјҡ0.00m/sпјӣ пјҲ5пјүиҪ»з“Ұж–Ҝе®№з§ҜйҮҚеӨҚжЈҖжөӢиҜҜе·®пјҡВұ10mlпјӣ пјҲ6пјүиҪ»з“Ұж–Ҝе®№з§ҜжҳҫзӨәдҪҚж•°пјҡ0.00ml; пјҲ7пјүеҜҶе°ҒйҮҚеӨҚжЈҖжөӢиҜҜе·®пјҡВұ2.5Kpaпјӣ пјҲ8пјүеҜҶе°ҒжҳҫзӨәдҪҚж•°пјҡ0.00KpaгҖӮ Features Tester Features 1, NALC type automatic gas relay test bed, using the latest embedded system control technology, integrated user's actual needs and introduced a new generation of gas relay test detection system. The system uses oil pump - flow meter continuous measurement method, respectively ПҶ25, ПҶ50, ПҶ80 mm diameter gas relay at home and abroad flow rate, volume and seal detection, and the experimental process without human intervention. 2, embedded PC system, the use of full-color touch display, the system can be simple and intuitive flow rate, volume, seal test-related operations, and edit the relevant test report printing, and can save the data at any time to access and print. As a result of embedded design, controlled by the PC, user-friendly, high degree of automation. Product structure 1, the structural characteristics (1) The external cabinet is made of cold rolling board, with the dimensions of 2400 Г— 650 Г— 1570mm (length Г— width Г— height), the total weight of the whole machine is 170kg; (2) clamping device using a screw ratchet way to clamp the specimen; (3) the tank is non-pressure structure, the side with a level gauge; (4) A protective cover is provided at the installation position of the test piece; 2, electrical and control systems (1) the working environment: -10 ~ +50 в„ғ, relative humidity <85%; (2) The main electric circuit adopts AC380V, the total power is 11KW; (3) oil pump motor with AC380V, power 5.5KW; (4) electric actuators AC220V / DC24V power control, power 0.25KW; (5) control system uses AC220V / DC24V power control, power 0.25KW; (6) oil heater: AC220V, power 5KW; (7) with 19-inch full-color touch display, full Chinese and English graphic display, the process automatically by the system, without human intervention; (8) the use of virtual projection mouse and keyboard. This technology for the two-dimensional projection imaging, in front of the touch screen work surface, the projection of a red and the size of the keyboard consistent with the virtual projection keyboard, the operator can use the keyboard to edit the contents of the test report. Operators can also use this keyboard shortcut to complete the keyboard and mouse to switch, and through the shortcut keys on the virtual keyboard to close the projector mouse and keyboard, and then open the fixed gesture. (9) embedded PC system can be intuitive on the heavy gas flow, light gas volume, seal detection of individual and integrated projects to operate, and at the same time edit the print test report; (10) PC system installed by our own independent development, with full intellectual property rights of professional measurement and control software, and can implement network remote system upgrades and maintenance. (11) Remote technical support: If the site operator needs technical support, the equipment only needs access to the peripheral network, and the remote end technical personnel can remotely control the equipment and upgrade the equipment software. Main technical performance 1, the measurement range (1) heavy gas flow detection В В В В В ОҰ25 mm diameter of the flow rate range: 0.6 ~ 3.9m / s; В В В В В ОҰ50 mm diameter of the flow rate range: 0.6 ~ 3.0m / s; В В В В В ОҰ80 mm diameter of the flow rate range: 0.6 ~ 2.0m / s. (2) light gas volume detection В В В В В Detection range: 0 ~ 950ml. (3) seal detection pressure and time range В В В В В Seal detection pressure range: 0 ~ 250KPa; В В В В В Seal detection time range: 0 ~ 60min. 2, precision (1) flow rate detection accuracy: 1.5 [factory standard 1.0]; (2) flow meter accuracy: 0.5 [factory standard 0.2]; (3) repeated gas flow rate detection error: В В В В В ОҰ25 mm diameter of the flow rate Вұ 0.05m / s гҖҗFactory standard Вұ 0.04m / sгҖ‘; В В В В В ОҰ50 mm diameter of the flow rate Вұ 0.04m / s гҖҗFactory standard Вұ 0.03m / sгҖ‘; В В В В В ОҰ80 mm diameter of the flow rate Вұ 0.02m / s гҖҗfactory standard Вұ 0.02m / sгҖ‘. (4) the number of heavy gas flow display digits: 0.00m / s; (5) light gas volume repeat detection error: Вұ 10ml; (6) light gas volume display digits: 0.00ml; (7) Seal repeat detection error: Вұ 2.5Kpa; (8) Sealed display digits: 0.00Kpa.

еҚ—жҫіз”өж°”жӯҰжұүжңүйҷҗе…¬еҸё

йҷҲиҢңиҢң

йҷҲиҢңиҢң

- [иҒ”зі»ж—¶иҜ·иҜҙжҳҺжқҘиҮӘжЈҖжөӢйҖҡ]

- еңЁзәҝе®ўжңҚпјҡ

-

- з•ҷиЁҖе’ЁиҜў

- иҒ”зі»ж–№ејҸпјҡ

-

иҜ·зӮ№еҮ»жҹҘзңӢз”өиҜқ

- йӮ®д»¶пјҡ

- еҸ‘йҖҒйӮ®д»¶

- ең°еқҖпјҡ

- дёңж№–й«ҳж–°жҠҖжңҜејҖеҸ‘еҢәе…іеұұеӨ§йҒ“60еҸ·е…ү谷科жҠҖдә§дёҡеӣӯ

жҺЁиҚҗдә§е“Ғ

- еҚ—жҫіз”өж°”NACJ4800е…ЁиҮӘеҠЁйӣ·з”өеҶІ

- еҚ—жҫіз”өж°”NAJNYе…ЁиҮӘеҠЁз»қзјҳйқҙпјҲ

- еҚ—жҫіз”өж°”NAVLFи¶…дҪҺйў‘й«ҳеҺӢеҸ‘з”ҹ

- еҚ—жҫіз”өж°”NASBFдёүеҖҚйў‘ж„ҹеә”иҖҗеҺӢ

- еҚ—жҫіз”өж°”NASLQеӨ§з”өжөҒеҸ‘з”ҹеҷЁ

- еҚ—жҫіз”өж°”NAIVGе…ЁиҮӘеҠЁйӣ·з”өеҶІеҮ»

- еҚ—жҫіз”өж°”NANYжҷәиғҪеһӢе·Ҙйў‘иҖҗеҺӢиҜ•

- еҚ—жҫіз”өж°”NASCJе…ЁиҮӘеҠЁйҷЎжіўеҶІеҮ»

- еҚ—жҫіз”өж°”NAENеһӢз”өеӯҗејҸдә’ж„ҹеҷЁж Ў

- еҚ—жҫіз”өж°”NAQLз”өжөҒдә’ж„ҹеҷЁзҺ°еңәжөӢ

- еҚ—жҫіз”өж°”NAQYз”өеҺӢдә’ж„ҹеҷЁзҺ°еңәжөӢ

- еҚ—жҫіз”өж°”NAPXеӨҡеҠҹиғҪе·Ҙйў‘йў‘зҺҮзӣё

- еҚ—жҫіз”өж°”NAFY-1000kV/2kО©ж ҮеҮҶ

- еҚ—жҫіз”өж°”NAJFSж•°еӯ—еұҖйғЁж”ҫз”өжЈҖ

- еҚ—жҫіз”өж°”NAJFXDеұҖйғЁж”ҫз”өи¶…еЈ°иҮӘ

-

жЈҖжөӢйҖҡжүӢжңәзүҲ

жЈҖжөӢйҖҡе®ҳж–№еҫ®дҝЎ

жЈҖжөӢйҖҡQQзҫӨ